Cleansol LLC is your trusted electropolisher partner in high-quality metal finishing solutions and one of the leading electropolishing companies. Our electropolishing services are designed to enhance the durability, aesthetics, and performance of your metal components.

Overview of Electropolishing

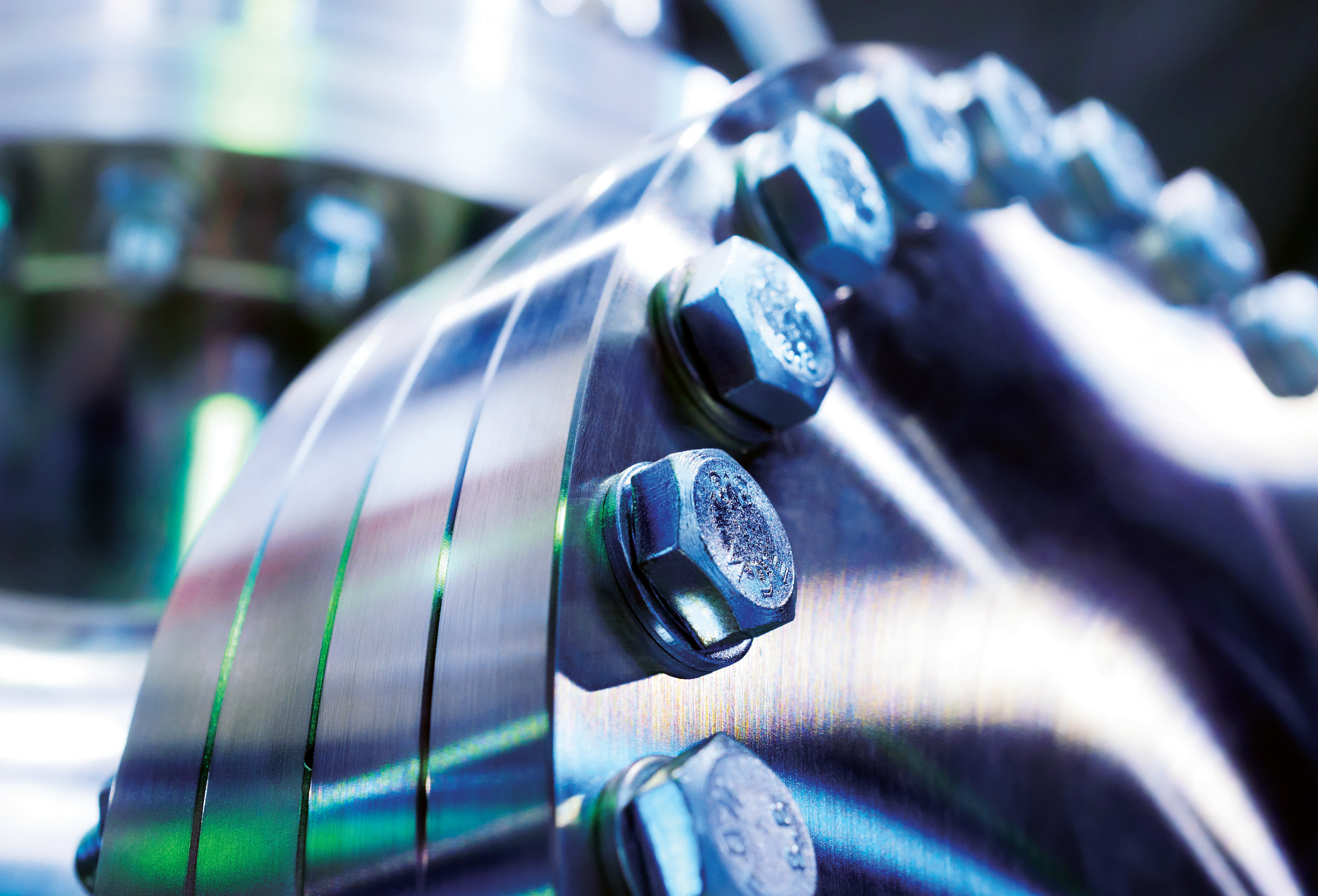

Electropolishing is an electrochemical process used to polish, passivate, and deburr metal surfaces. It involves the removal of material from the workpiece surface through an electrochemical reaction, resulting in a smooth, shiny, and clean surface finish.

Key Electropolishing Services Offered

Cleansol LLC is your trusted electropolisher partner in high-quality metal finishing solutions and one of the leading electropolishing companies. Our electropolishing services are designed to enhance the durability, aesthetics, and performance of your metal components.

Stainless Steel Electropolishing

As an electropolisher, we specialize in electropolishing stainless steel, a process ideal for applications requiring high corrosion resistance and a polished finish. This service is commonly used in industries such as pharmaceuticals, food and beverage, and medical devices. Electropolishing stainless steel provides superior corrosion resistance compared to mechanical polishing and improves surface finish without altering dimensional tolerances.

Aluminum Electropolishing

Our aluminum electropolishing services are effective in enhancing the surface finish and corrosion resistance of aluminum components. This process is widely utilized in aerospace, automotive, and electronics industries to remove surface imperfections and burrs, resulting in improved aesthetic appeal and cleanliness.

Other Metal Electropolishing Services

In addition to stainless steel and aluminum, we offer customizable electropolishing solutions for various metals including copper, brass, titanium, and nickel alloys. These services are tailored to meet the unique needs of your specific metal components, ensuring optimal performance and durability.

Advantages of Electropolishing

Our electropolishing services offer several advantages:

- Improved Corrosion Resistance: Electropolishing creates a passive oxide layer on the metal surface, increasing its resistance to corrosion.

- Enhanced Aesthetics and Surface Finish: Achieve a smooth, reflective surface that is aesthetically pleasing and easy to clean.

- Reduced Maintenance and Cleaning Requirements: Smooth surfaces are less prone to dirt and easier to sanitize, reducing maintenance costs.

Industries Served

Our electropolishing services cater to a diverse range of industries, including pharmaceutical, biotechnology, and semiconductor. We understand the unique requirements of each industry and provide tailored solutions that meet industry standards and regulations.

In the pharmaceutical industry, electropolishing plays a crucial role in enhancing the cleanliness and corrosion resistance of stainless steel equipment used in manufacturing and packaging processes. This process ensures compliance with stringent regulatory standards and reduces the risk of contamination. Components such as stainless steel mixing tanks, pharmaceutical processing equipment, and stainless steel tubing and fittings benefit significantly from electropolishing.

For the biotechnology industry, electropolishing is essential for improving the surface finish of stainless steel components used in research, production, and laboratory environments. It helps maintain a sterile environment and prevents contamination, supporting the industry’s stringent requirements. Bioreactors and fermenters, stainless steel instrumentation, and laboratory equipment, and fittings are among the components that benefit from this process.

In the semiconductor industry, electropolishing enhances the cleanliness and smoothness of stainless steel and other metal parts used in semiconductor manufacturing. This is critical for maintaining clean room standards and improving process reliability. Components such as vacuum chambers, gas delivery systems, and semiconductor manufacturing equipment benefit greatly from electropolishing.

Why is Electropolishing Essential?

Electropolishing is essential for businesses seeking regulatory compliance, meeting industry standards, and achieving long-term cost savings.

Electropolishing ensures your components meet the standards for cleanliness and corrosion resistance, providing a high-quality surface finish that enhances product reliability, reduces maintenance costs, and increases operational efficiency. Choose Cleansol LLC as your electropolisher for superior electropolishing services that enhance functionality and reliability.

Shine Bright Like a Diamond with Electropolishing Services of Cleansol LLC

Electropolishing is a critical process for enhancing the functionality and reliability of metal components across various industries. At Cleansol LLC, we specialize in providing superior electropolishing services that meet the requirements of pharmaceutical, biotechnology, semiconductor, and other industries. Contact Cleansol today to learn more about how our electropolishing services can benefit your business. We look forward to helping you achieve superior surface finishes, enhanced corrosion resistance, and long-term cost savings. Trust us to be your partner in optimizing the performance and durability of your metal components.