Cleansol LLC is a specialized cleaning contractor, serving the biotechnology, pharmaceutical, and semiconductor industries. Our services help demanding industries maintain the safe and clean working environments that contribute to equipment longevity. We adhere to industry-specific regulatory requirements and safety standards, offering a comprehensive range of convenient on-site and laboratory services.

Our team is dedicated to providing the highest quality industrial cleaning, ensuring your equipment remains free from contaminants, particles, and other impurities. Throughout our many years of service, we’ve helped diverse clients gain peace of mind while eliminating the responsibility of cleaning and maintenance tasks. As an industry leader in contract cleaning and passivation, we offer a full range of services including surface cleaning, chemical cleaning, deep cleaning, and more. Learn more about our specific capabilities below.

Request for QuotePassivation

Passivation is a process used to enhance the corrosion resistance of stainless steel and other metal alloys. By removing free iron and surface contaminants, passivation helps protect equipment from rust, oxidation, and tarnish—extending service life and maintaining clean, functional surfaces.

At Cleansol, we tailor our passivation services to the specific requirements of each project. Our most-recommended product features citric acid, which is not only highly effective but also safe and environmentally friendly. We also use nitric acid-based passivation compounds when preferred. Our proprietary passivation product achieves impressive results on many types of metals and alloys, delivering a rust- and tarnish-free finish without any manual scrubbing.

Our commercial and industrial-grade services are suitable for many types of equipment, including:

- Hygienic piping systems

- Bio-reactors

- Valve blocks and small parts assembly

- Tanks

- Tube spools & manifolds

If you’re looking for ways to protect your investments, passivation from Cleansol can help extend your equipment’s lifespan and prevent unplanned downtime due to maintenance issues.

Hydronics Cleaning

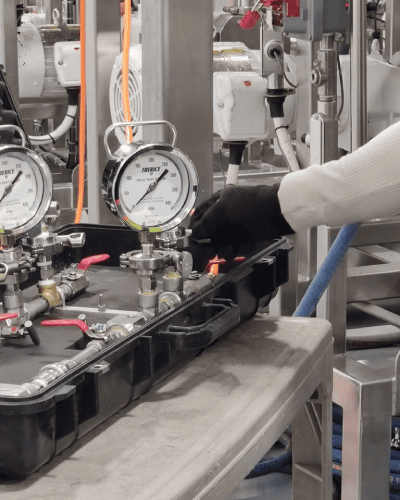

Hydronics piping systems include all the cooling & heating piping (utilities) in industrial processes that must all remain in peak condition for optimal system efficiencies. Without regular cleaning, debris and dirt can create fooling, leading to overall decreased performance.

Chemical cleaning services from Cleansol can help you maintain optimal system performance and extend the lifespan of your hydronics equipment. Our professional hydronics cleaning services are designed to eliminate debris and other contaminants from these systems. We use proven techniques and advanced cleaning technology to achieve safe and thorough results.

Hydronics require specialized cleaning agents to carefully remove contaminants and debris without damaging the system. Through Cleansol’s line of chemical cleaning services, we offer the following for hydronics:

- Acid Cleaning (Descaling)

- Alkaline Cleaning

- Detergent Cleaning

- Disinfection

- Blow-Out Process

One of the most common hydronics cleaning techniques we offer is flushing, which involves forcing cleaning fluid through a system at velocities that provide enough turbulence to dislodge unwanted particles. First, our experts inspect hoses and pipe fittings for any pressure leaks. Next, we assemble bypass lines and connect flushing hoses before filling the system with cleaning fluid. In addition to flushing, we also offer other hydronic cleaning methods, including filtering and multi-stage cleaning processes. Our experts can help you determine the most suitable techniques for your system.

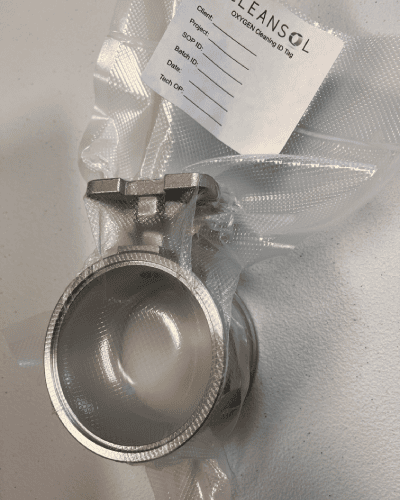

Oxygen Cleaning

Oxygen cleaning is a method of safely and effectively cleaning the equipment and associated equipment used in oxygen-rich environment and other applications. In the pharmaceutical and biotechnology industries, contaminants within oxygen systems pose a serious health and safety risk. The main need for O2 cleaning is to prevent combustions hazards but other important aspects are to ensure safety in oxygen systems (O2 systems are ultra-pure systems) and to maintain system integrity and performance.

At Cleansol, we use several advanced oxygen cleaning techniques to maintain safe purity levels. Our procedures adhere to rigorous ASTM G93-03 standards for oxygen-enriched environments, as well as CGA G-4.1, which outlines the necessary guidelines for cleaning oxygen service materials and equipment. We use both mechanical and thermal cleaning procedures to achieve thorough results. After each step of the process, we perform stringent testing to verify process effectiveness and guarantee that cleanliness levels meet your standards.

Cleansol oxygen cleaning thoroughly eliminates many types of hazardous materials, including:

- Dust

- Grease

- Hydrocarbon oils

- Metal particles

- Lint

In addition to maintaining oxygen service equipment, we also handle other types of industrial gas systems, including nitrogen, helium, argon and other high-purity medical gas piping systems.

Equipment Cleaning

Cleansol offers exterior surface cleaning services to not only prevent corrosion but also offers more aesthetically pleasing appearances. Regular cleaning is not just about appearance—it directly impacts the lifespan and efficiency of your equipment. Clean equipment resists corrosion better, operates more smoothly and presents a better overall image of your facility.

Our cleaning process includes:

- Surface treatments

- Chemical Cleaning

- Manual Scrubbing

- Passivation Services after the cleaning process is complete

Derouging Services

While passivation protects and restores the chromium oxide film, there’s another issue stainless steel often faces: rouging. It’s a condition where layers of ferrous or iron oxide get embedded on the steel’s surface, leaving it with unsightly reddish hues. This not only impacts the appearance but can also interfere with the steel’s performance over time. Enter derouging.

Derouging is a specialized chemical process aimed at removing these iron oxide layers. Leveraging state-of-the-art techniques and our extensive experience, we ensure the elimination of these layers effectively. Not only does it take care of the aesthetic aspect, but derouging also preps the stainless steel for an effective passivation process, ensuring the steel retains its inherent protective qualities.

Key benefits of our derouging services:

- Enhanced Stainless Steel Condition. Get rid of the unwanted red tones and restore your equipment’s original shine.

- Preparation for Passivation. Ensure optimal steel passivation by starting with a pristine surface. A clean slate is crucial for the passivation process to be effective.

- Optimized Surface Cleanliness. Post-derouging, you’re guaranteed a surface that’s free from contaminants and ready for any application. Your equipment will be at its best, both visually and functionally.

Improve Your Facility With Specialized Cleaning Services From Cleansol

Pharmaceutical, biotechnology, and semiconductor facilities must meet strict cleanliness and safety standards to remain compliant and maintain operational reliability. Cleansol LLC offers specialized cleaning services that help clients in these industries maintain high-purity environments and meet regulatory requirements such as ASTM A380, A967, G93-03 and CGA G-4.1.

Our services—including passivation, hydronic system cleaning, oxygen cleaning, and derouging—are tailored to each project’s needs. With responsive service and advanced cleaning equipment, we help minimize downtime while supporting your facility’s long-term performance.

Contact Cleansol today to learn more about how we can help maintain your equipment and meet your facility’s specialized cleaning requirements.