While stainless steel is naturally protected from corrosion and other damage by a natural Chromium Oxide layer, this layer can be disrupted or damaged by cutting, welding, heating, grinding, or contact with chemicals, which can cause it to lose this protection. While passivation can improve corrosion resistance, imperfections that this process can’t eliminate, referred to as rouging, can be left behind after welding or heat treatment. Not only can rouging impact appearance, but it can also interfere with steel’s performance over time.

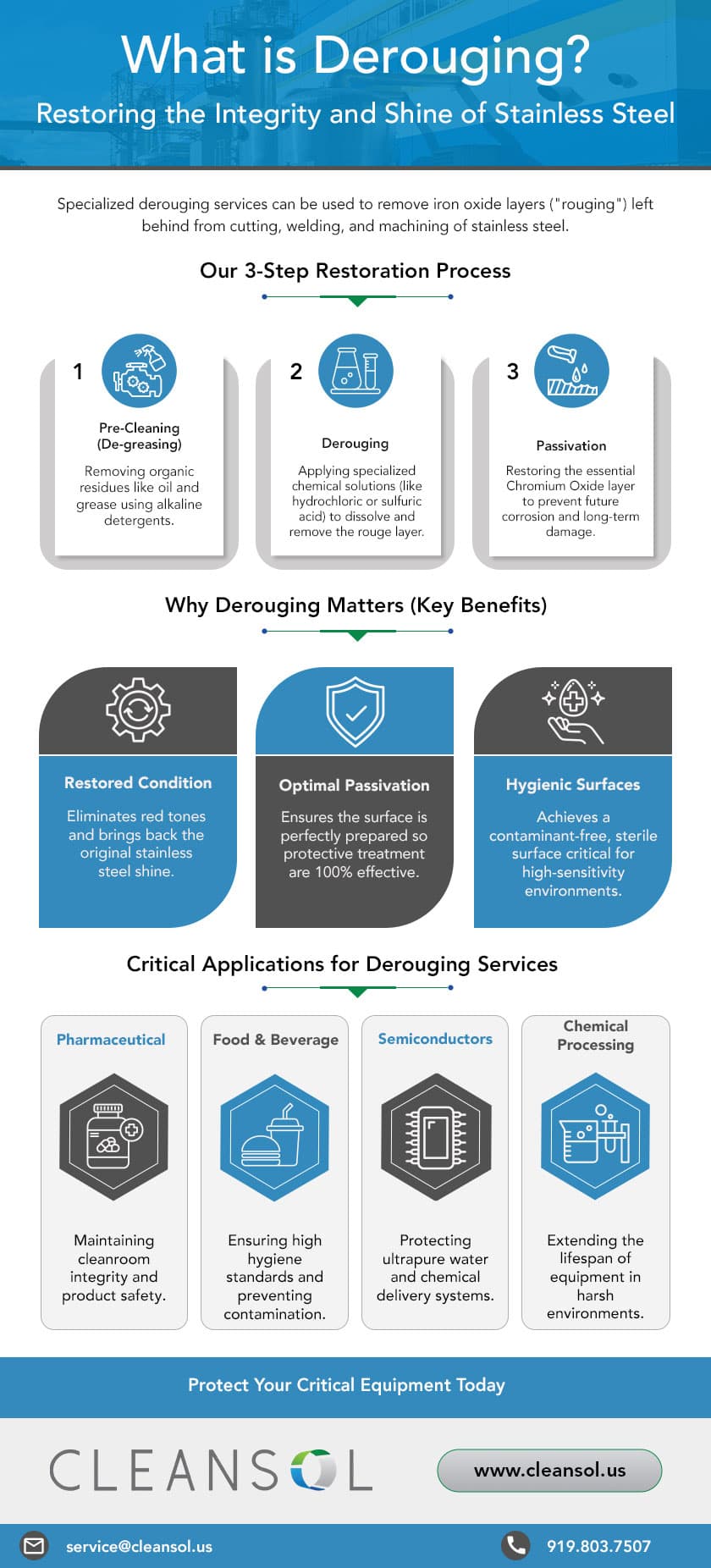

Specialized derouging services can be used to remove these iron oxide layers. At Cleansol, we can utilize derouging to restore stainless steel surfaces, so your steel equipment retains its inherent protective qualities and is properly prepared for passivation. Keep reading to learn more about Cleansol’s derouging process and its applications.

The Derouging Process

Derouging treats steel with a chemical solution, such as hydrochloric or sulfuric acid. This works to remove rouging, restore the steel’s surface condition, and prevent further corrosion. The derouging process includes:

- Pre-cleaning (de-greasing). The first step in the derouging process is to pre-clean the stainless steel to remove any organic residues, such as oil or grease, that might interfere with the derouging process. This process is often completed using an alkaline detergent cleaner to ensure the surface is properly prepared for derouging.

- Derouging. Once the steel’s surface is properly prepared, specialized chemical solutions are used to dissolve and remove the rouge. Monitoring the concentration of dissolved iron in the solution throughout this process is essential in helping determine when the derouging process is complete.

- Post-derouging passivation. Once derouging is complete, passivation restores the protective chromium oxide layer on the stainless steel that helps prevent corrosion and protects equipment against long-term damage.

Benefits of Derouging

Derouging stainless steel prior to passivation enhances both the cleanliness and durability of stainless steel equipment. Just a few benefits Cleansol’s derouging process provides include:

- Enhanced stainless steel condition. The derouging process is essential in helping to eliminate unwanted red tones, restoring your equipment’s original shine.

- Preparation for passivation. Derouging stainless steel before performing passivation is crucial to make sure that the passivation process is effective in restoring the steel’s natural protective qualities.

- Optimized surface cleanliness. Derouging services from Cleansol can provide a hygienic, contaminant-free surface that is critical for sterile environments.

Common Applications

Cleansol’s derouging services for stainless steel are suitable for a range of applications, such as:

- Food and beverage processing. Removing rouge from stainless steel is essential in the food and beverage industry in order to ensure proper hygiene and prevent the contamination of food and beverage products.

- Pharmaceutical manufacturing. Derouging in pharmaceutical manufacturing enhances the integrity of cleanroom and process equipment, which can help maintain product safety and regulatory compliance.

- Semiconductor manufacturing. In semiconductor manufacturing, derouging helps remove iron oxide deposits that could contaminate ultrapure water and chemical delivery systems.

- Chemical processing. Derouging can also help extend the lifespan of critical equipment in harsh chemical processing environments by addressing corrosion.

Derouging Services and Cleansol

Derouging is an important process in many industries, as it helps protect equipment from degradation while also preventing product contamination. At Cleansol LLC, we strive to provide quality derouging and passivation services designed to protect critical equipment and maintain equipment cleanliness in industries where cleanliness or contamination are a concern. Our services are designed to help enhance your overall operations, leading to better quality outcomes.

Contact us today to learn more about our services or to request a quote for your next project.